Home / News / Evolution for the Future – Bottlenecks and Potential Breakthrough Directions in Titanium Anode Technology

Jan. 12, 2026

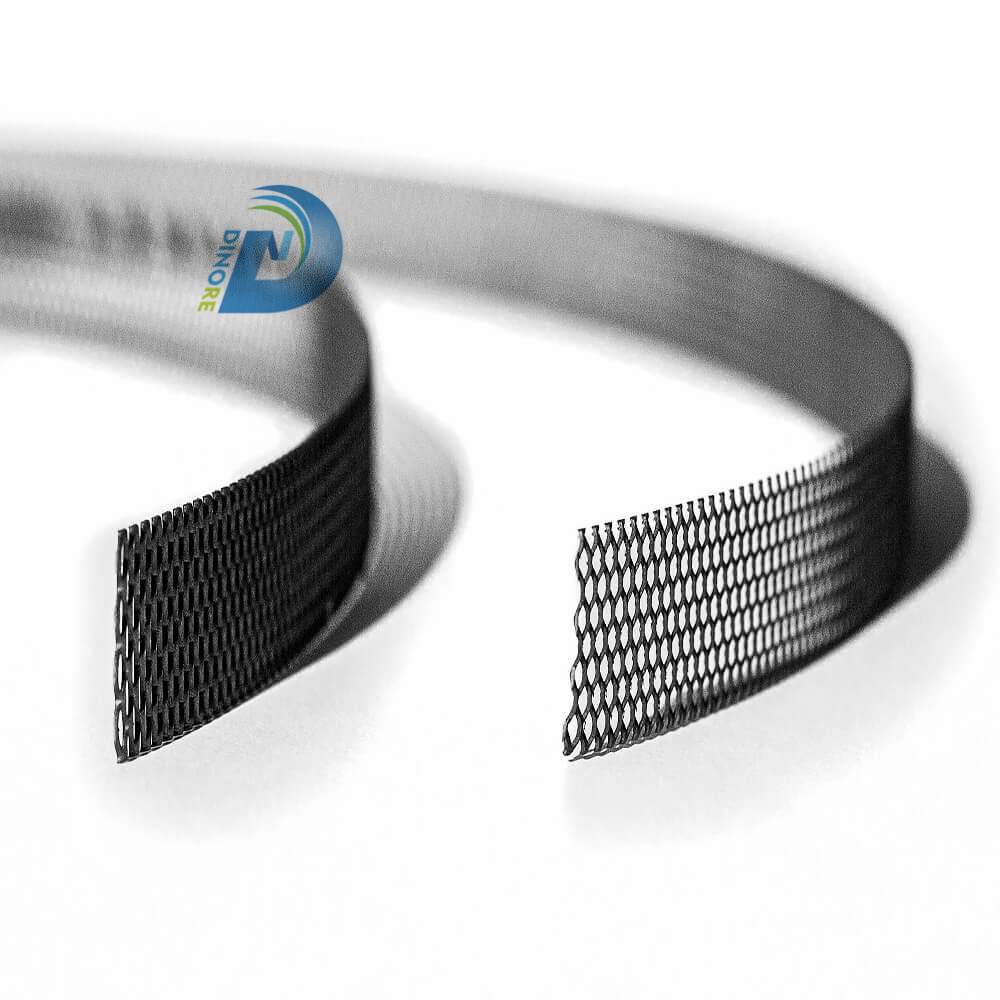

Abstract: Although titanium anode mesh ribbon technology is mature, its evolution continues, driven by the pursuit of longer life, lower cost, and greater adaptability to complex environments. This article focuses on current technological bottlenecks and explores several promising frontier research directions.

1. Bottlenecks: Cost, Complex Environments, and Life Prediction

Noble Metal Dependency and Cost: High-performance MMO coatings heavily rely on noble metals like iridium and ruthenium. Their high and volatile prices are a core economic constraint on large-scale application.

Adaptability to Complex and Extreme Environments: The stability of existing commercial coatings faces challenges in extreme industrial environments characterized by high temperature, high acidity/alkalinity, or the presence of organic pollutants and sulfides.

Uncertainty in Life Prediction: The method of extrapolating decades of actual service life from laboratory accelerated life tests (e.g., electrolysis at intensified current densities) is contentious. Establishing more reliable life prediction models that incorporate real-world environmental stress factors is an urgent need in the engineering community.

2. Breakthrough Direction I: Exploration of Low/Non-Noble Metal Coatings

Research focuses on reducing noble metal dependency through nanostructure design and composition optimization.

High-Entropy Oxide Coatings: Oxide solid solutions composed of four or more metal elements in equimolar or near-equimolar ratios. Their unique "cocktail effect" and lattice distortion effects may significantly enhance coating structural stability and corrosion resistance while maintaining catalytic activity, offering a new approach to reducing noble metal content.

Nanocomposite and Doping Technologies: Introducing nanoscale conductive phases (e.g., TiO₂ nanotube arrays as a substrate) or doping with elements like tin, antimony, or manganese into oxide coatings aims to tune the band structure and surface properties, enhancing intrinsic activity and electron conductivity.

3. Breakthrough Direction II: Integration of Intelligence and Condition Monitoring

Transforming the anode from a "passive consumable" into an "intelligent, reportable component."

Embedded Sensors: Exploring the integration of micro-electrode sensors at key nodes of the anode mesh to in-situ monitor coating potential, interfacial impedance, or local pH changes, enabling early failure warning.

Online Electrochemical Impedance Spectroscopy (EIS) Monitoring: By periodically applying a small AC signal to the anode system and analyzing its impedance response, the aging state of the coating, interfacial changes, and scaling can be assessed non-destructively, providing data for predictive maintenance.

4. Breakthrough Direction III: Recycling and Remanufacturing Technologies

As early-installed titanium anode systems gradually reach their design life, the treatment of spent anodes is becoming increasingly important. Developing efficient coating stripping and titanium substrate regeneration technologies to achieve strategic recovery of noble metals and substrate recycling can not only reduce the total life-cycle cost but also aligns with green manufacturing trends. Currently, recycling processes like high-temperature alkali fusion and electrochemical dissolution are transitioning from the laboratory to industrial application.

Conclusion: The future of cathodic protection titanium anode technology will involve deep integration of materials science, electrochemical engineering, and information technology. Breaking the constraints of noble metals, achieving precise life management, and evolving towards a circular economy model are the core challenges to be addressed in its next developmental phase. These breakthroughs will enable long-lasting, economical, and reliable corrosion protection solutions to benefit a wider range of industrial sectors.