Home / News / Titanium Anode System Integration: Building the Future Hub of Intelligent Water Treatment

Jan. 21, 2026

In modern water treatment facilities, breakthroughs in individual technologies are important, but system-level integration and optimization often determine overall effectiveness. As the core component of electrochemical water treatment, the true potential of titanium anodes lies in their deep integration with other technologies, control systems, and operational strategies to form efficient, synergistic intelligent treatment systems.

Traditionally, the water treatment industry has focused on the material properties and reaction efficiency of titanium anodes themselves. While this “single-electrode thinking” has driven advances in electrode technology, it has not fully unleashed the systemic potential of electrochemical treatment. Modern water treatment requires viewing titanium anodes as part of a complete system, including interconnected subsystems such as power management, fluid dynamics design, real-time monitoring, and intelligent control.

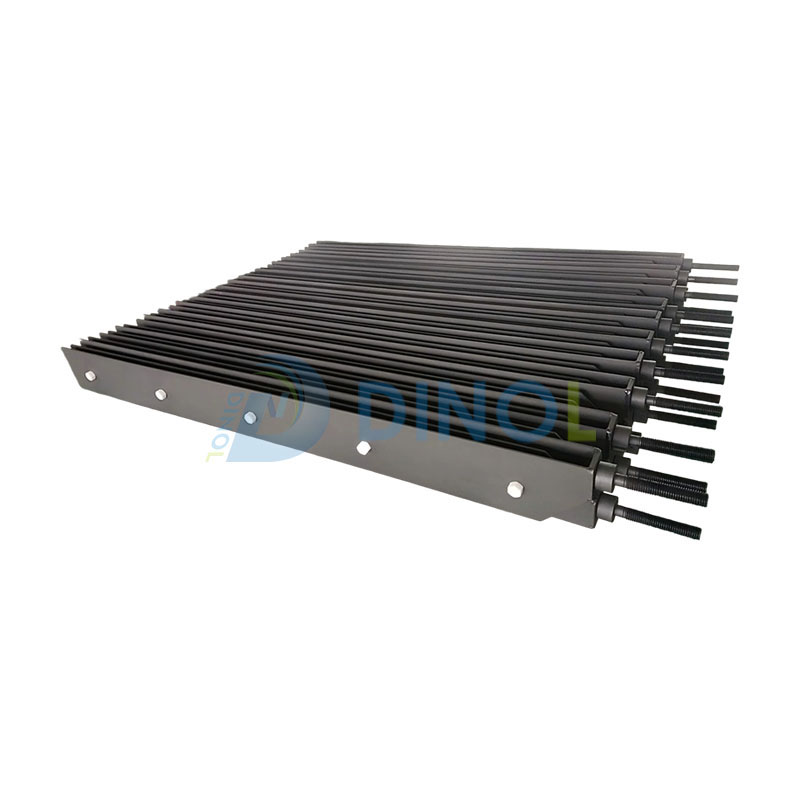

System integration first manifests in hardware configuration. The geometric shape, arrangement, and relative positioning of titanium anodes and counter electrodes must be optimized based on specific water quality and treatment goals. For example, wide-gap electrode arrangements are used for wastewater with high suspended solids to prevent clogging, while smaller electrode gaps are needed for low-conductivity water to reduce energy consumption.

Energy consumption is a major operational cost in electrochemical water treatment, and the integration of intelligent energy management systems can significantly improve energy efficiency. Advanced titanium anode systems are now equipped with adaptive power supplies that dynamically adjust current density and voltage waveforms based on real-time changes in influent water quality and flow rates.

An innovative approach involves using pulse electrolysis instead of traditional direct current electrolysis. Through carefully designed pulse frequencies and duty cycles, researchers have successfully reduced energy consumption by over 30% while maintaining treatment efficiency. This technology is particularly suitable for treating wastewater containing easily polarizable substances, effectively reducing electrode passivation.

Photovoltaic-titanium anode direct coupling systems represent another integration concept. In areas with abundant sunlight, direct current generated by solar panels can power titanium anode systems without inversion or rectification, reducing energy conversion losses. Experimental systems show that this direct coupling method improves efficiency by 15% compared to traditional grid-connected power supply.

The combination of titanium anodes and membrane technology creates synergistic effects in water treatment. Pre-electrochemical treatment can alter the properties and sizes of pollutants through oxidation and coagulation, significantly reducing the burden on subsequent membrane filtration and extending membrane life. Meanwhile, microbubbles generated during electrochemical processes help mitigate membrane fouling.

Reverse osmosis (RO) concentrate treatment is a typical application of this synergy. RO concentrate contains high concentrations of salts and hard-to-degrade organic compounds, and direct discharge poses environmental risks. Integrated titanium anode systems can effectively break down these organics while generating active chlorine to prevent microbial growth on membrane surfaces. A seawater desalination plant’s practice shows that this integrated approach reduces RO membrane cleaning frequency by 40%.

A more cutting-edge exploration involves integrating titanium anodes directly into membrane modules to form “electrochemically active membranes.” These composite membranes combine filtration with electrochemical oxidation, achieving integrated separation and degradation. Preliminary studies indicate that this integrated design is particularly effective in removing pharmaceutical residues from hospital wastewater.

One of the core competencies of modern titanium anode systems lies in data analysis capabilities. By embedding multiple sensors, the system can monitor key parameters such as electrode potential, coating impedance, and temperature distribution in real time. Combined with influent water quality data, this provides a complete picture of system health.

Based on these data, machine learning algorithms can predict coating failure trends and performance degradation curves, enabling predictive maintenance rather than traditional scheduled replacements. A case study from a large industrial water treatment plant shows that this predictive maintenance strategy reduces anode replacement costs by 25% while avoiding water quality fluctuations due to sudden electrode performance declines.

The application of digital twin technology elevates system integration to new heights. By creating precise digital replicas of titanium anode systems in virtual space, operators can test different operating strategies and simulate system responses under extreme water quality conditions without affecting actual production, thereby optimizing control parameters and improving system resilience.

Water treatment facilities vary greatly in scale, from large plants processing tens of thousands of tons daily to small decentralized treatment units, all requiring titanium anode technology support. The modular design concept enables titanium anode systems to flexibly adapt to different scale requirements.

Standardized titanium anode modules can be combined and expanded like building blocks based on treatment capacity, with each module integrating power supply, control, and monitoring functions, interconnected via standard interfaces. This design not only reduces installation and maintenance difficulty but also allows for rapid adjustments according to changing needs. In rural decentralized water treatment, such modular systems have shown significant advantages, allowing flexible configuration of treatment capacity based on village size.

Modern titanium anode systems increasingly focus on integrating resource recovery functions. When treating industrial wastewater containing metal ions, by carefully controlling the potential, the system can oxidize organics at the anode while selectively recovering valuable metals at the cathode. This dual function of “treatment + recovery” enhances the economic viability of projects.

An innovative example is the integration of titanium anode systems with ion exchange or adsorption technologies. Electrochemical pretreatment alters pollutant properties, making them easier to capture by subsequent adsorption materials, while electrochemical regeneration allows adsorbents to be reused repeatedly, reducing solid waste generation. This combined process excels in treating wastewater containing complex organic compounds.

Future titanium anode systems will evolve toward full autonomy. Based on the Internet of Things and artificial intelligence, systems will be capable of self-diagnosis, self-adjustment, and even collaboration with other treatment units in regional water networks. In a smart water treatment plant, titanium anode systems will no longer be isolated units but intelligent nodes within a water treatment neural network.

Another important trend is the rise of distributed treatment architectures. Small, efficient titanium anode systems can be installed directly at pollution sources, enabling on-site treatment and resource recovery, reducing the need for long-distance water transportation. This “treatment-as-a-service” model is particularly suitable for industrial parks and urban decentralized pollution sources.

Titanium anode system integration represents a shift in water treatment technology from “component optimization” to “system intelligence.” This integration is not just about technical connections but also a paradigm shift in thinking—requiring engineers to transcend traditional disciplinary boundaries and merge electrochemistry, fluid dynamics, materials science, data technology, and control theory. As integration deepens, titanium anode systems will no longer be simple treatment devices but the core hub of intelligent water management, playing a key role in ensuring water quality safety, improving resource efficiency, and reducing environmental footprints.