Home / News / A Wide Range of Applications for Electrolytic Technology

Sep. 27, 2021

Electrolysis is the process of passing an electric current through an electrolyte solution or molten electrolyte, causing a redox reaction at the cathode and anode. Electrochemical cells can undergo an electrolytic process when a direct current voltage is applied. In the previous article we talked about the types of electrolytic cells and welcome you to learn more about them. Today DINORE introduces you to the areas where electrolysis technology can be applied.

The electrolytic copper foil industry uses curved structured electrolytic cells to manufacture copper foil by electrolysing copper sulphate solutions. Copper is plated on titanium cathode rolls with a diameter of 2-3 metres and the copper foil is peeled off at one end of the rotor; the distance between the anodes and the cathode rolls is as small as 5 mm, yet it is necessary to ensure that a thin copper foil of uniform thickness is deposited on the smooth cathode rolls. Due to the demanding quality and performance requirements of the product, the stability of the electrolytic conditions in production is strictly required.

It is formed when high purity aluminium foil (99.9% or more) is electrochemically or chemically etched and then treated to a spongy/tunnel-like surface to increase its surface area, and then the electrolytic foil is anodised to produce a dense aluminium oxide film on the surface. Aluminium electrolytic capacitors generally consist of an anode foil and a cathode foil.

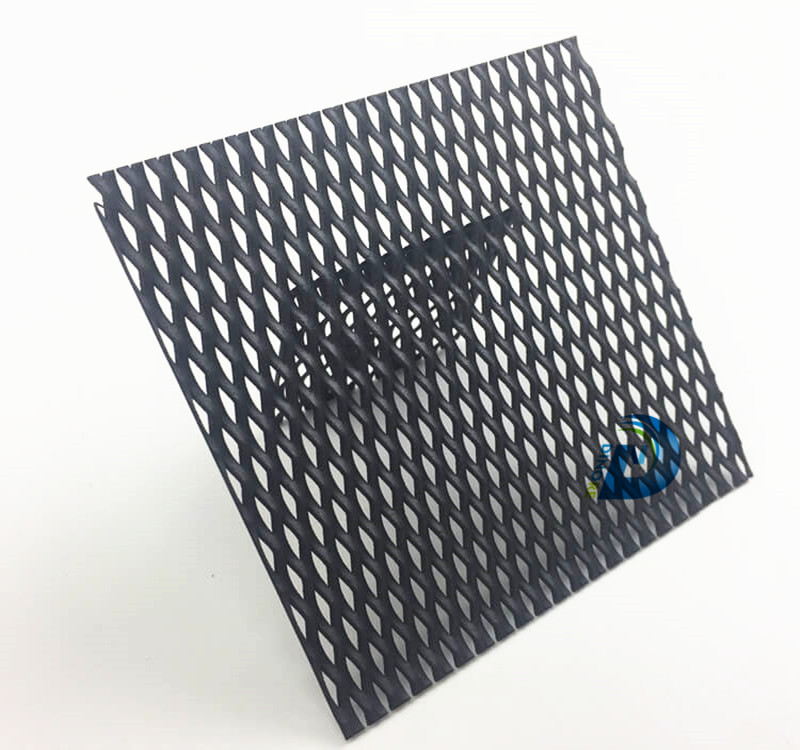

The chemical industry for the production of caustic soda and chlorine gas by electrolysis of saturated salt solutions is known as the chlor-alkali industry and has been in production for more than 100 years. During the development of chlor-alkali production, electrodes such as platinum, magnetic iron oxide, carbon and artificial graphite have been tried, but the results have been less than satisfactory. The use of titanium electrodes coated with a mixture of precious metals, on the other hand, has many advantages. Titanium anode materials have the advantages of strong chemical resistance, low chlorine overpotential, good electrical conductivity, high mechanical strength, easy processing and low price.

Electroplating is a method of depositing metals or alloys onto a plated part by electrochemical means. Insoluble anodes for electroplating are coated with a coating of precious metal oxides with high electrochemical catalytic properties on a titanium substrate, the coating contains highly stable metal oxides. People use anodes can be divided into soluble and insoluble, such as copper, chromium, nickel, etc. is to plating metal as the anode, the purpose is to make the solution of metal ions to be effectively replenished, the anode shape of this process is not stable, plating uniformity is poor, maintenance and maintenance complex.

Etching is an important process in the production of printed circuit boards. As etching proceeds, the concentration of copper ions in the etching solution rises and when Cu2+ reaches a certain level, the etching solution will lose its activity. In the reuse treatment of etchant, copper is recovered from the waste solution using electrodeposition. Titanium anodes for copper recovery from etchants can be carried out in chloride electrolytes, sulphate electrolytes and mixed chloride and sulphate electrolytes. Electrowinning for the extraction of non-ferrous metals requires anodes that are stable, corrosion resistant, available for long periods of time and have good electrocatalytic activity during the anodic process to reduce the overpotential and tank voltage of the anodic reaction.

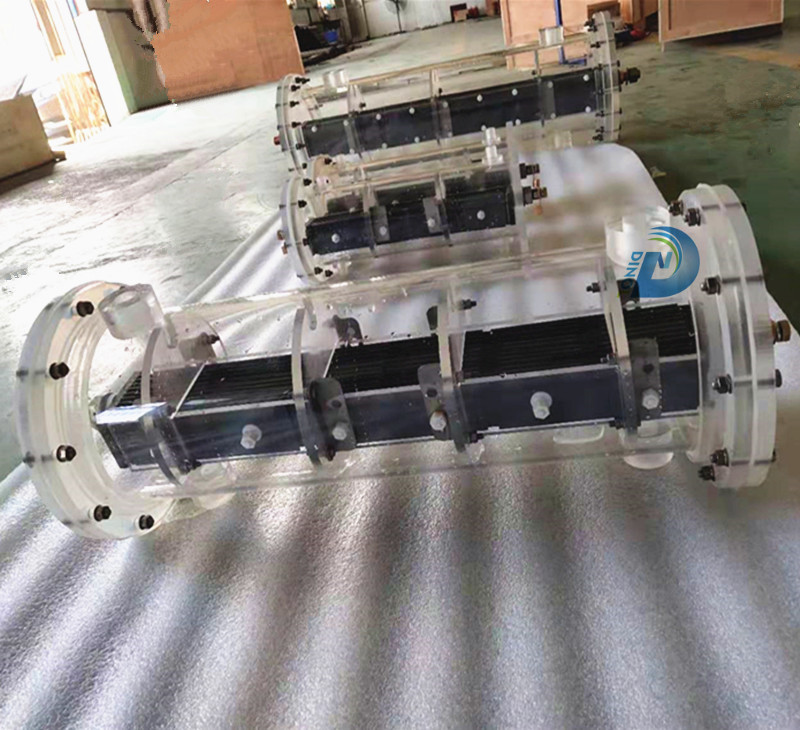

Please contact us if you have related projects and wanna buy titanium anode or electrolytic cells. We have many years of research and development experience with Electrochemical technology for water disinfection and electrochemical cell for water-treatment. The products have been successfully applied in various fields, such as waste water treatment,electrolytic disinfection, Food purification and disinfection and other fields.