Home / News / An Engineering Solution Redefining Cathodic Protection Efficiency and Service Life

Dec. 10, 2025

Titanium-Based MMO Anodes: An Engineering Solution Redefining Cathodic Protection Efficiency and Service Life

In the field of infrastructure corrosion protection under harsh environments, the efficiency and lifespan of cathodic protection systems directly impact asset safety and operational costs. MMO (Mixed Metal Oxide) anodes, which utilize commercially pure titanium as a substrate coated with a composite of precious metal oxides, have become the core of next-generation high-performance cathodic protection technology due to their exceptional physical and electrochemical properties. This represents not merely a material upgrade, but a systematic engineering philosophy that fundamentally enhances protection reliability and optimizes whole-life-cycle costs.

Breaking Through Traditional Bottlenecks: Core Advantages Based on Material Innovation

Traditional anode materials, such as high-silicon cast iron or graphite, commonly face inherent limitations like rapid consumption, limited output efficiency, and bulky size during long-term use. Titanium-based MMO anodes achieve multi-dimensional performance leaps through the integration of materials science and electrochemical engineering:

Exceptionally High Current Output Efficiency: The specially treated MMO catalytic coating on its surface drives electrochemical reactions with very low overpotential, achieving operational current densities potentially over ten times higher than traditional materials. This means that in scenarios requiring equivalent protective current, the volume and weight of MMO anodes can be significantly reduced, offering unprecedented flexibility for engineering design.

Negligible Self-Consumption: The theoretical consumption rate of the anode during service is extremely low, typically below 10 milligrams per ampere-year. This enables a design service life that easily exceeds 25 years, potentially matching the design life of the protected structure itself. It fundamentally changes the maintenance model associated with traditional anodes, which require periodic inspection and replacement.

Unparalleled Potential Stability: The MMO coating possesses highly stable electrochemical performance, with minimal fluctuation in operating potential during long-term energization. This stability ensures the potential of the protected structure can be precisely maintained within the optimal protection range, preventing both corrosion risks from under-protection and issues like coating disbondment or hydrogen embrittlement caused by over-protection.

Excellent Mechanical and Environmental Adaptability: The titanium substrate itself offers high strength, light weight, and corrosion resistance, allowing it to directly withstand installation and environmental stresses. Its performance remains stable across a wide range of temperatures, salinities, and soil resistivities, enabling reliable application in complex conditions from deep sea to desert, and from ambient to high temperatures.

Addressing Engineering Pain Points: Creating Quantifiable Long-Term Value for Clients

The value of MMO anode technology lies in its precise solution to the core challenges clients face in the design, installation, and operation & maintenance of cathodic protection systems:

Addressing Space and Load-Bearing Constraints: In projects with space limitations or sensitivity to added weight, such as offshore platforms, pipe racks, or retrofits of existing facilities, MMO anode systems leverage their "small yet powerful" characteristics to achieve protection goals with the most compact layout, simplifying support structures and reducing installation difficulty and cost.

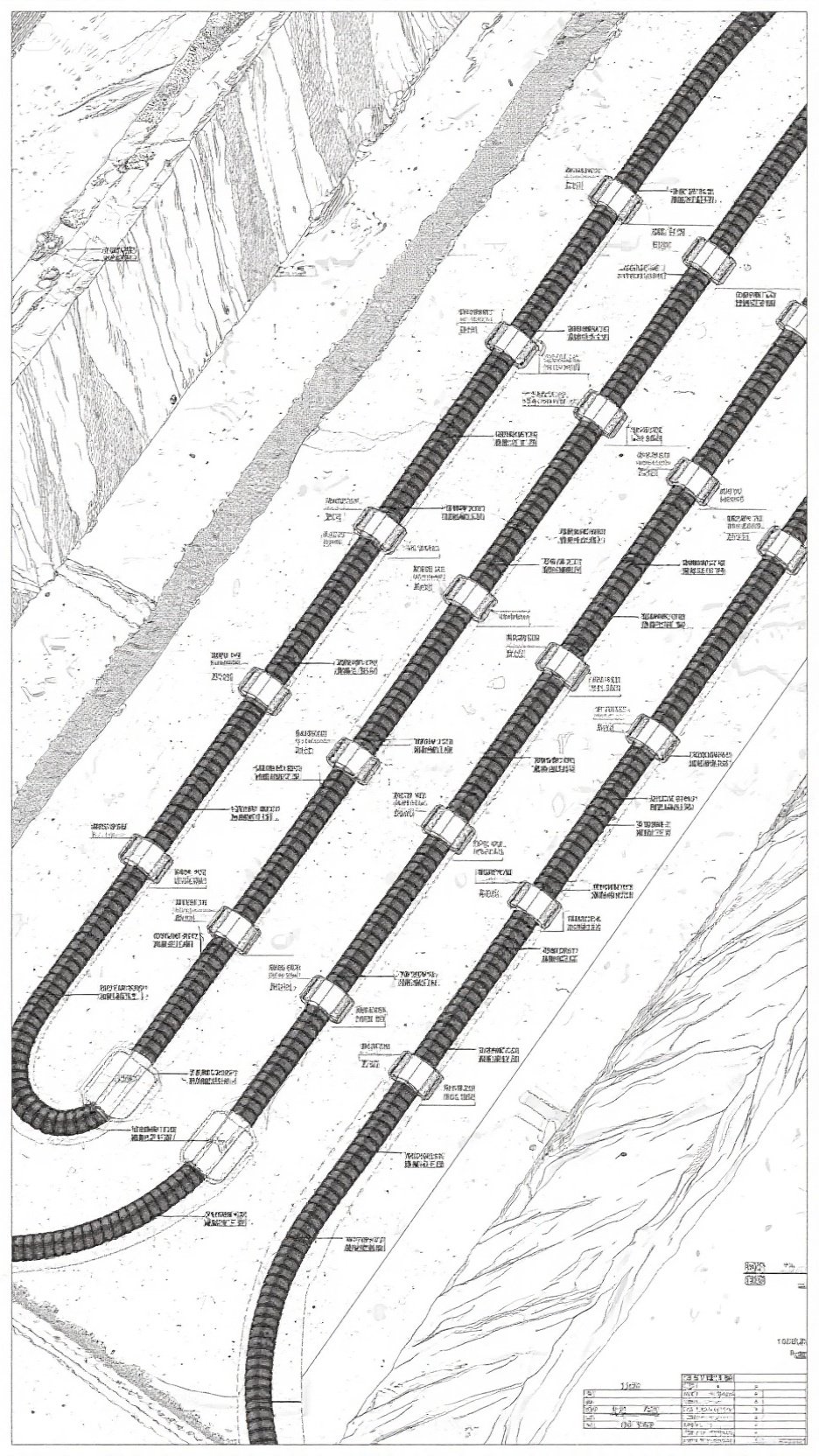

Overcoming Challenges in High-Resistivity Environments: In high-resistivity areas like arid, sandy, rocky, or permafrost regions, connecting multiple MMO tubular anodes in series to form "anode strings" and using specialized low-resistivity backfill can create distributed groundbeds with low grounding resistance and uniform current distribution. This significantly improves system efficiency, making effective protection feasible even in challenging soil conditions.

Substantially Reducing Whole-Life-Cycle Costs: The total cost of cathodic protection is primarily composed of the initial investment and decades of operational expenses. The extremely long service life and minimal maintenance requirements of MMO anodes can minimize operational costs. Their efficient current output also reduces power consumption. From a whole-life-cycle perspective, their comprehensive economic benefit is significantly superior to traditional solutions requiring frequent replacement.

Ensuring Long-Term Reliability and Safety: The long-term stable operation of the system is fundamental to asset safety. The exceptional stability of MMO anodes minimizes the workload for system commissioning and subsequent adjustments. Their robust and durable nature also reduces the risk of protection interruption due to premature anode failure, providing assets with reliable, long-lasting protection.

From Component to System: Providing Future-Oriented Solutions

The philosophy of modern engineering protection is evolving from simple component procurement toward integrated solutions. The value of high-quality titanium-based MMO anode products lies not only in the anodes themselves but also in the ability to provide systematic support—including design consultation, installation guidance, and performance monitoring—based on a profound understanding of engineering.

Looking ahead, with the rapid development of deep-sea exploration, new energy infrastructure (such as offshore wind power, hydrogen storage and transportation), and major trans-oceanic projects, higher demands are being placed on cathodic protection technology. Titanium-based MMO anode technology, with its customizable coating formulations, flexible form factors (such as tubular, ribbon, mesh), and potential for integration with smart monitoring systems, will continue to lead industry innovation. It will provide whole-life-cycle corrosion protection for more complex and critical infrastructure.

Choosing titanium-based MMO anodes is, in essence, selecting a technological pathway centered on long-term reliability, high efficiency, cost-effectiveness, and environmental adaptability. It helps engineering decision-makers transform the long-term challenge of corrosion control into a predictable, manageable investment in asset preservation, ultimately laying a solid foundation for the century-long safety of infrastructure.