Home / News / Two Usage Introduction: Storage Tank and Concrete Members

Aug. 27, 2021

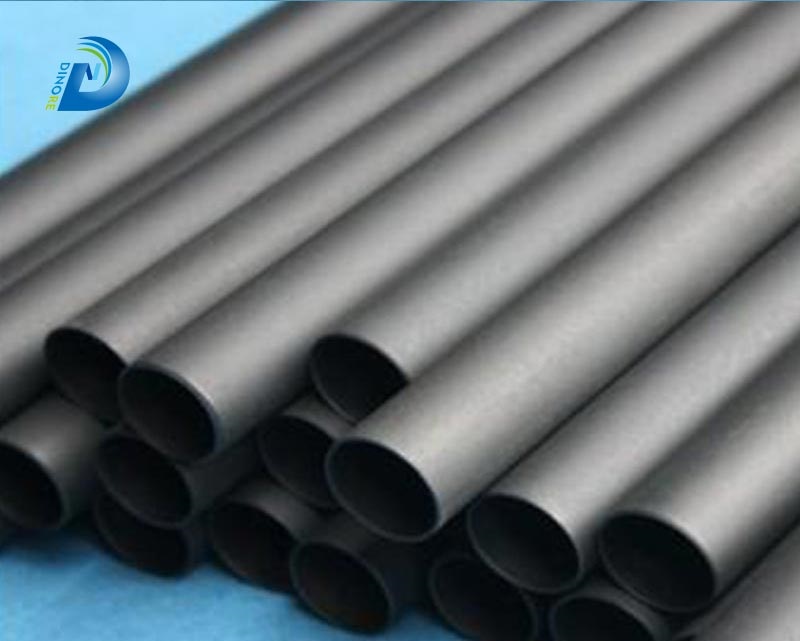

We have introduced some of the applications of the MMO titanium anode in the previous article. Now here are two other brief introduction of the usage of MMO anode.

The network anode cathodic protection system used in tank bottom plate is a reliable way of cathodic protection, which has the irreplaceable advantages of other systems. In 1987, the first MMO strip anode impressed current cathodic protection system was designed and installed for a large storage tank (0105m) at a gulf coast refinery in the United States. The system reached protection potential after 60 days of polarization at 4mA/m2F.

A mesh anode composed of MMO titanium strips has the following advantages:

Small geometric size, can be buried close to the bottom of the tank, or buried in the middle of the tank double bottom.

It can be directly buried in backfill sand, no need for coke filler, eliminating the possibility of system short circuit.

Low dc circuit resistance, low energy consumption.

Do not interfere with adjacent metal installations.

Protect the current evenly across the tank bottom.

There is no need to drill the formation surface, which is environmentally friendly.

Easy to install and control.

Reinforced concrete is the most durable and widely used building material, but in some circumstances, many reinforced concrete structures are prematurely broken due to corrosion. The examples are numerous, with the United States estimating that losses of reinforced concrete Bridges and parking lots due to snowmelt salt amount to between $335 million and $1 billion a year.

The corrosion failure mechanism of reinforced concrete is clear. When reinforced concrete members are exposed to moisture, chlorine penetrates into the concrete, reducing the PH of the rebar surface and resulting in high rates of corrosion, with the volume of corrosion products approximately twice that of steel. Thus causes the corrosion part concrete volume expansion, causes the concrete spalling. Glass fiber sheath and backfill mortar have been used to mitigate the corrosion, but the effect is not ideal.

For concrete members exposed to the atmosphere, corrosion protection has come a long way from protecting highway bridge decks to protecting historic buildings. In 1959, cathodic protection was used for the first time in the United States to protect concrete bridge decks in California. These 50 years have seen the development of new anode materials, conductive coatings and mounting methods. The cathodic protection system for concrete components was originally made of conductive organic coating or coating, which has been widely used in the protection of parking lot components.

MMO expansion Titanium mesh anode has the following advantages:

Small size, easy to bury concrete components.

Uniform distribution of current.

Dc circuit resistance is low.

Long life, low operating costs.

Easy to install and debug.

Di Noer technology Co., Ltd. is a manufacturer of mmo coating titanium anodes,electrolyzers and tantalum/niobium metal or other materials. If you want to know more about titanium anodes, please contact us now.